Professional

Leading

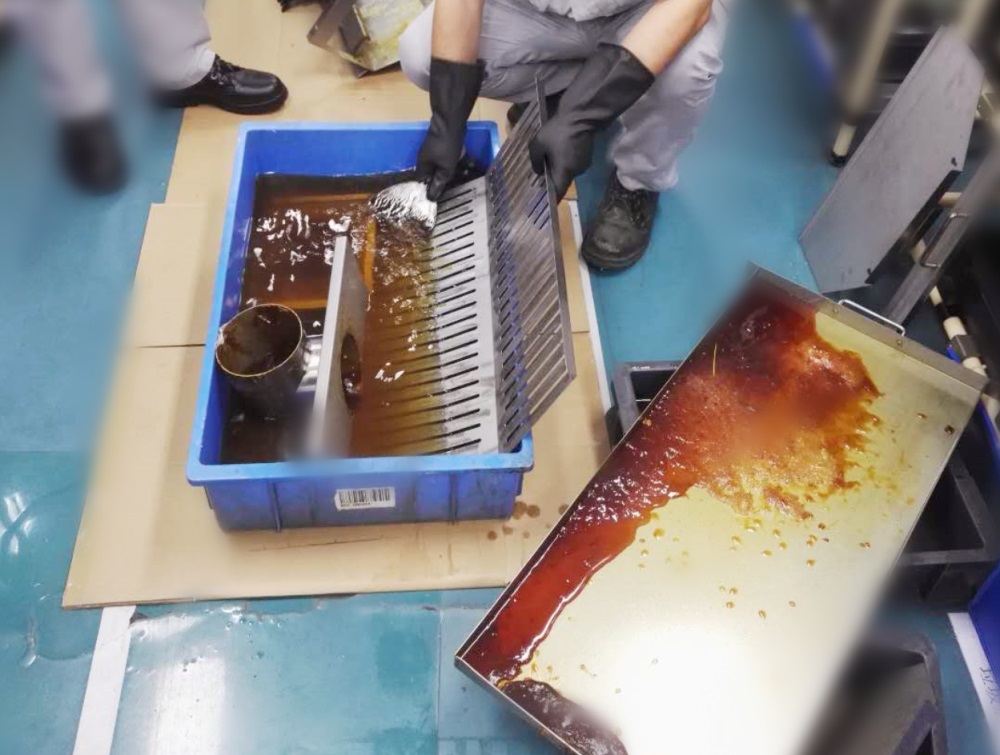

In order to ensure the quality of SMT process products and the reliability and stability of equipment technical parameters, the reflow soldering furnace used by standardized manufacturers undergoes a major cleaning once a month, including dismantling and cleaning of detachable parts such as condensers, fans, and filters. Due to the relationship between the operating cycle time of SMT reflow soldering and DIP line wave soldering, resin residue and solid substance residue adhesive will form on the furnace liner. Under long-term high temperature action, carbonization phenomenon and state may occur, turning into stubborn residue, which has an adverse impact on the technical parameters and usage conditions set for product processing time in the reflow soldering furnace. Often, this type of equipment (reflow soldering, wave soldering) requires regular cleaning and maintenance.

回流焊爐大保養(yǎng)清洗現(xiàn)場(chǎng)

Generally speaking, major maintenance and cleaning of the reflow soldering furnace equipment are carried out every month. Detachable parts such as the condenser, fan, filter screen, etc. need to be removed for disassembly and cleaning. The filter screen, chain claw, etc. of the wave soldering need to be regularly disassembled and cleaned to remove resin dirt and high-temperature carbides.

To ensure the good operation of the SMT reflow soldering equipment, solvent based products are used for brushing, spraying, and coating on the furnace liner and the cleaned surface according to traditional cleaning methods. The dirt is removed and dissolved by wiping and wiping, and then sprayed with cleaning agent for multiple cleaning to remove the dirt.

With the advancement of products, this type of cleaning method has produced liquid water-based cleaning agents in recent years to replace solvent based cleaning agents, greatly improving the removal effect and cleaning ability. At the same time, it also improves the safety of homework. Water based cleaning agents often have characteristics such as non flammability and good environmental protection, which bring great convenience to cleaning and maintaining reflow soldering furnaces. However, due to the uneven and flowing phenomenon of liquid cleaning agents during application and spraying, it is difficult to maintain sufficient time for the cleaning agent to soak and react with dirt, resulting in unsatisfactory cleaning effects and phenomena. SMT reflow soldering detachable parts cleaning aerosol furnace water-based cleaning agent has emerged.

水基氣霧型清洗劑W5000

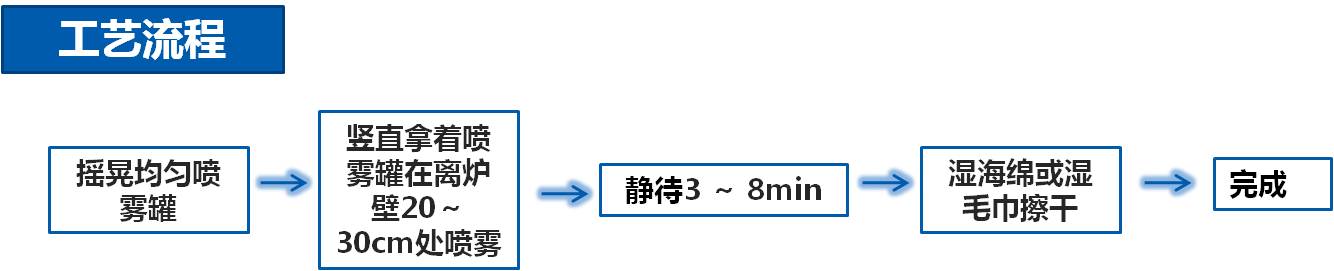

Process flow diagram of water-based aerosol cleaning agent for furnace maintenance and cleaning

Unibright's aerosol furnace water-based cleaning agent is filled with aerosols. It needs to be shaken up before use, so that the liquid gases can be evenly mixed to produce a uniform spray state of cleaning agent. At the same time, the sprayed cleaning agent attaches to the surface of the object to be cleaned, forming a uniform thin layer of foam, providing better wetting and dissolution conditions. The cleaning agent has sufficient time and opportunity to decompose dirt, Especially for stubborn dirt and even carbonized dirt, it has good removal and decomposition ability. The foam cleaner is sprayed on the cleaned object and stays for 5-10 minutes. It only needs to be wiped with a wet rag or a wet sponge to remove foam and dirt to get a very bright and clean furnace surface, which greatly facilitates the operation of operators, improves efficiency, simplifies the operation mode, and shortens the maintenance and cleaning time. The aerosol water-based cleaning agent for reflow soldering furnace equipment conforms to the requirements of the EU REACH environmental protection regulations in terms of material, and has good environmental characteristics. It is non-flammable, with good safety, low odor, and convenient operation, it can be applied to the needs of reflow soldering and tunnel furnace maintenance and rapid maintenance, greatly reducing work time and improving work efficiency. The aerosol type furnace water-based cleaning agent significantly improves the cleaning effect compared to traditional liquid water-based cleaning agents and solvent based cleaning agents. Satisfying the lean production needs of modern electronic products with high precision and reliability, it greatly maximizes the efficiency of equipment availability, shortens maintenance time, simplifies maintenance work processes, and simplifies the workload of workers.

![[x]](/en/template/default/picture/closeimgfz1.svg)