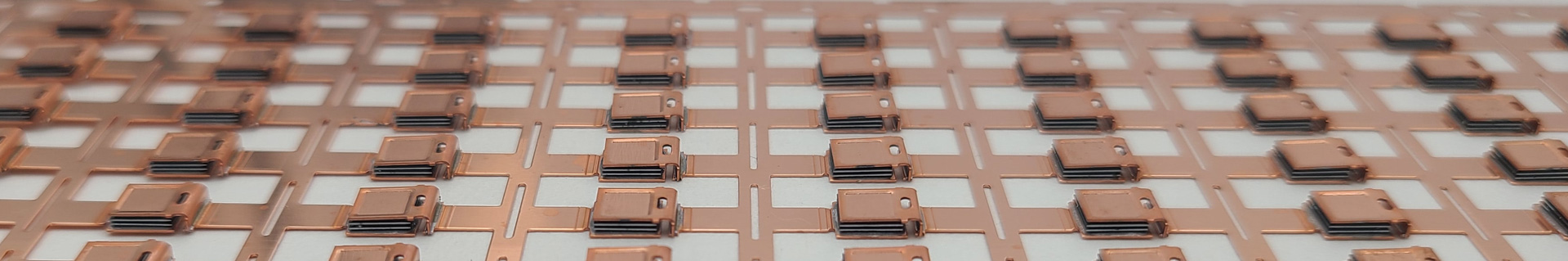

Power LED cleaning

At present, 5G communication and new energy vehicles are in full swing, and power devices and semiconductor chips are their core components. To ensure the quality and high reliability of power devices and semiconductor chips, it is necessary to introduce cleaning processes and use cleaning agents before packaging.

Before packaging power devices and semiconductors, flux and solder paste are usually used as welding aids. These aids will have some residue during the welding process, including pollutants such as fingerprints, sweat, keratin, and dust contaminated during the manufacturing process.

At the same time, the lead frames of power devices and semiconductors are assembled with fragile functional materials such as sensitive metals such as aluminum, copper, platinum, and nickel. These sensitive metals and special functional materials have high requirements for the compatibility of cleaning agents.

In general, cleaning agents with poor material compatibility are prone to adverse phenomena such as oxidation, discoloration, swelling, deformation, or detachment of sensitive materials. Water based cleaning agents are environmentally friendly cleaning agents developed for wire frames, power semiconductor devices, discrete devices, IGBT modules, power modules (optoelectronic modules, sensing modules, communication modules), and reflow soldering DCB post soldering cleaning. They have good material compatibility and high cleaning efficiency, and can clean residual materials such as solder paste, flux, and solder paste to avoid damage to sensitive materials.

![[x]](/en/template/default/picture/closeimgfz1.svg)